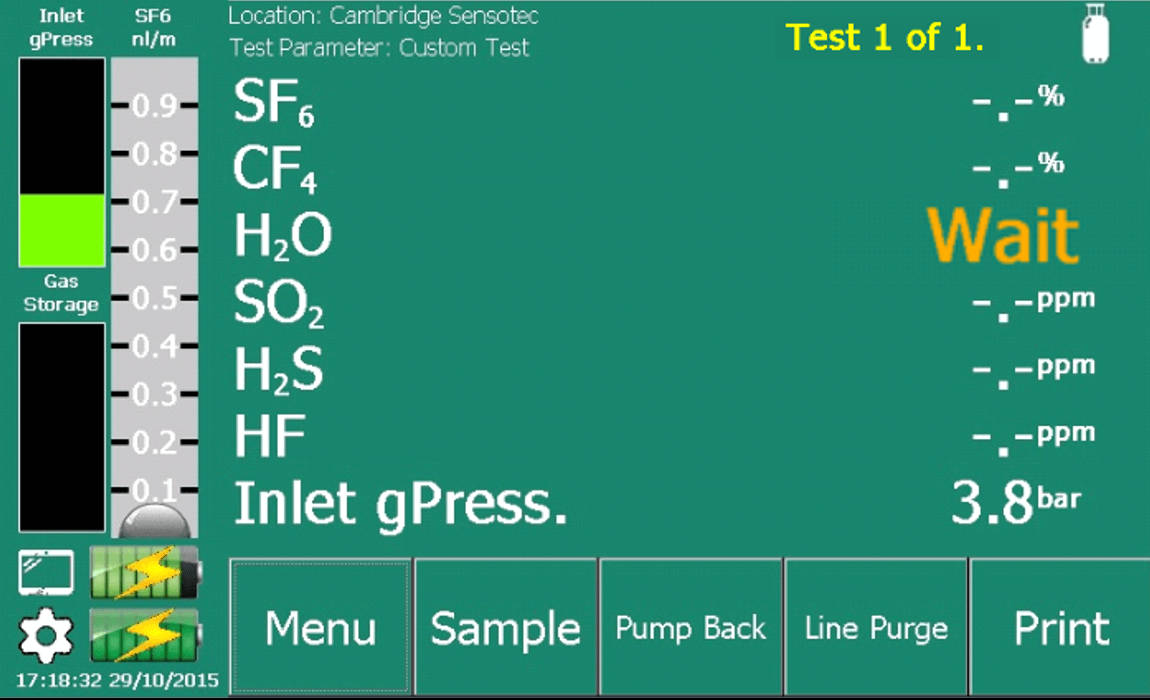

Analisi della qualità del gas SF6

Synecom offre servizi di analisi e certificazione del gas SF6 contenuto in bombole, apparecchiature e serbatoi, classificandolo secondo le norme CEI 60376 e CEI 60480, e misurando «H2O, SO2, % vol. SF6, HF, H2S, CO, CF4, N2, O2, H2, CO2». Questa attività permette alle aziende di raggiungere gli standard imposti dall’Unione Europea per il gas SF6, e di mantenere alti livelli di efficienza e sicurezza nei propri impianti. Il servizio può essere erogato sia presso la nostra sede che direttamente presso i siti operativi del Cliente.

Recupero e Riempimento

Gas SF6

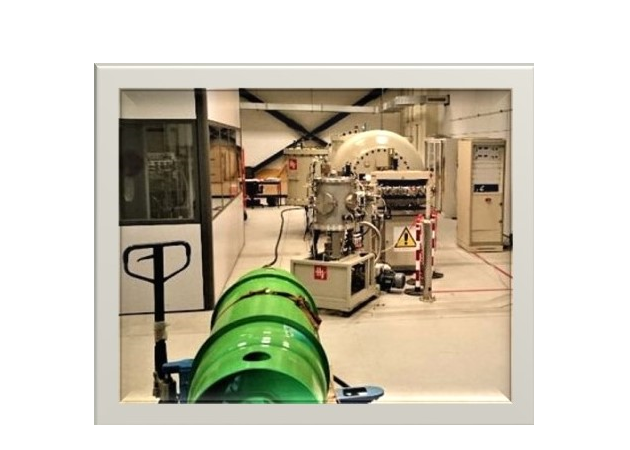

Una delle attività principali svolte da Synecom, riguarda gli interventi per il recupero e riempimento di gas SF6 su apparecchiature di alta/media tensione elettrica e acceleratori di particelle.

Attraverso i propri tecnici qualificati e patentati, attrezzature di ultima generazione e nel pieno rispetto delle normative vigenti, Synecom si adopera per recuperare il gas SF6 da apparecchiature di alta/media tensione elettrica e acceleratori di particelle fino alla pressione di norma, oppure fino alla pressione di trasporto. Tutte le operazioni di recupero del gas SF6 devono essere precedute dall’attività di analisi gas SF6 in esse contenuto.

Tutti gli interventi sono svolti da personale qualificato e patentato e dichiarati sulla banca dati Fgas in accordo al nuovo DPR 146/2018.

Attività di Service

Grazie all’esperienza pluridecennale e grazie alla continua formazione dei propri tecnici, Synecom si adopera per effettuare l’attività di service sulle apparecchiature, di Synecom e di altri brand, atte alla manipolazione del gas SF6.

In particolare le attività svolte sono le seguenti:

- Revisione di apparecchiature

- Retrofit: ovvero l’adeguamento delle apparecchiature obsolete alle nuove normative

- Riparazioni

- Ricalibrazioni e tarature

Trattamenti di vuoto

Una volta terminate le operazioni di manutenzione sull’apparecchiatura, prima di riempirla con gas SF6 in qualità tecnica, è necessario effettuare la bonifica della stessa da aria ed umidità. Le tecniche utilizzate da Synecom sono le seguenti:

- Vuoto aria spinto

- Lavaggio del comparto in azoto (non sempre necessario)

Certificazione dei livelli di perdita impianti

Synecom è attrezzata e qualificata per redigere certificazioni che attestano il livello di perdita di gas SF6 su impianti e apparecchiature contenenti tale gas. I test vengono effettuati mediante l’utilizzo di strumenti specifici ad alta sensibilità.

Bonifica di ambienti contaminati da SF6 o da sottoprodotti

Quando il gas Esafluoruro di Zolfo viene sottoposto ad azione di un arco elettrico, la molecola si decompone dando origine a prodotti di decomposizione solidi e gassosi.

Per poter bonificare i comparti contaminati e ambienti da prodotti di decomposizione solidi, Synecom interviene attraverso l’uso di specifici DPI e di aspirapolveri industriali apposite garantendo la bonifica dei comparti ed ambienti nel pieno rispetto dell’ambiente e del personale coinvolto.

Tale intervento è svolto da personale qualificato e patentato e deve essere dichiarato sulla banca dati Fgas in accordo al nuovo DPR 146/2018. La bonifica può considerarsi conclusa solo dopo che è stata effettuata l’inertizzazione dei rifiuti acidi e dei reagenti.

Gestione gas SF6 contenuto in apparecchiature a fine vita

La gestione del gas SF6 contenuto in apparecchiature a fine vita viene svolta da Synecom generalmente in tre principali operazioni:

- Analisi del gas Esafluoruro di Zolfo in esse contenuto

- Recupero del gas SF6

- Spedizione dell’apparecchiatura al sito di demolizione e successiva demolizione della stessa.

Tali operazioni sono svolte da personale qualificato e patentato e dichiarate sulla banca dati Fgas in accordo al nuovo DPR 146/2018.